[ad_1]

Sustainability is the motive force for the protein transition, which continues to realize traction globally. However to reach the long-term, it should be supported by financial advantages for the producer. Within the face of exterior components such because the risky vitality market and legislative efforts to cut back greenhouse gases, producers might search to enhance the worth of different proteins by decreasing the price of producing them. However Kevin van Koerten, Challenge Supervisor Processing at NIZO, explains that there’s one other strategy: empowering sustainability within the meals transition via progressive processing and sequential extraction and purification, to ship greater worth different proteins.

How do you improve the worth of a plant protein?

Any dialog round protein worth should begin with performance, as a result of meals product improvement is constructed round practical elements. This might embody structured supplies delivering ‘chew’, binders that maintain merchandise collectively, or emulsifiers that maintain drinks blended. Whereas there’s some innovation in mildly extracting less-refined proteins with extra normal fractions that may ship, for instance, mixed functionalities, this strategy would require a radical change in how merchandise are developed. Due to this fact, with the present product improvement strategy, if you want to change an animal-origin ingredient with an alternate, it is advisable extract a protein ingredient with the capabilities you want.

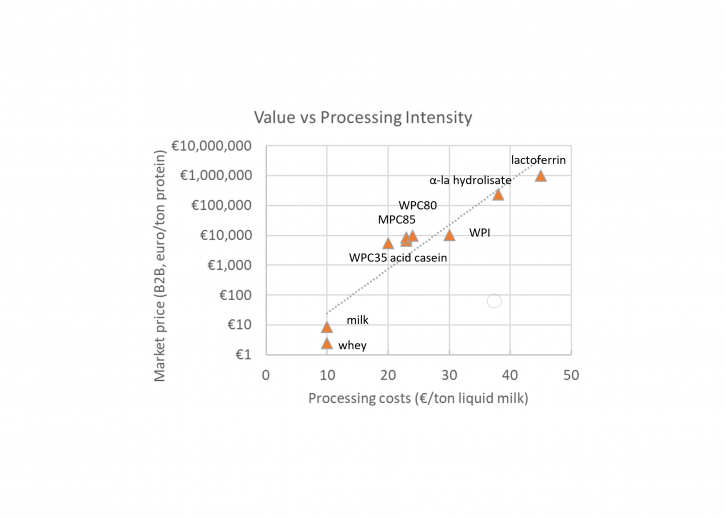

Each worth and value rise with protein performance. Nonetheless, the dairy business reveals us that this isn’t a linear relationship: extra practical proteins price extra to extract, however their market worth then will increase exponentially. Moreover, it’s attainable to optimise the total worth of a protein supply via sequential purification of proteins.

What’s sequential purification of proteins?

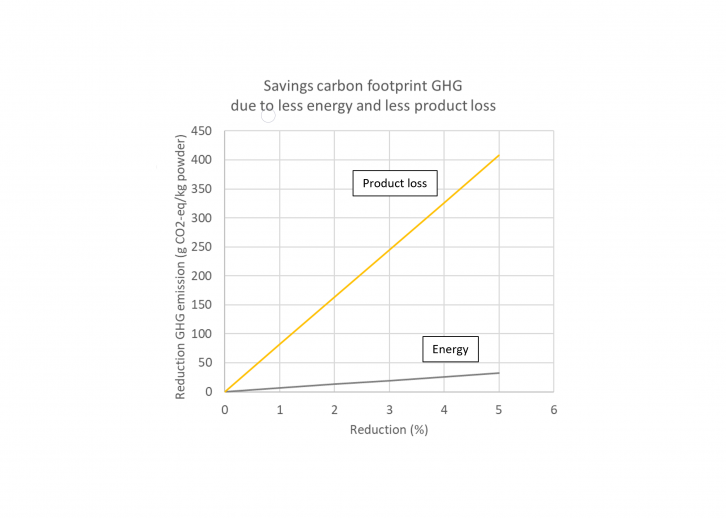

Sequential purification entails extracting a number of sorts of proteins from the protein supply, utilizing totally different extraction strategies. The dairy business has perfected this strategy over the previous 50-70 years. It lets you maximise the worth extracted from the protein supply, and use extra of the supply materials, which reduces waste and product loss. Decreasing product waste has been proven to result in greater reductions in greenhouse gases and vitality prices than efforts to chop vitality utilization.

Is it attainable to realize the identical outcomes with plant proteins?

Plant protein producers are already taking the primary steps, extracting a number of proteins with totally different functionalities from a single supply. So whereas you used to have a single ‘potato protein’ or ‘pea protein’, now you will have an acid-soluble protein fraction and a neutral-soluble protein fraction. Nonetheless, there’s a number of exploratory work to be performed, to determine all of the totally different proteins that may be extracted, after which to optimise the method design to get essentially the most worth. It’s a posh problem.

What are the challenges of optimising processing design for plant proteins?

Firstly, all milk is basically the identical, and responds to processing in the identical approach. However each different protein supply and composition is totally different, and presents its personal challenges. On the opposite

hand, there are some frequent challenges most plant proteins share, comparable to greater viscosity, which negatively impacts processing effectivity via, for instance, elevated blockage of kit.

One other problem is that in protein extraction and processing, plant proteins can lose performance, flavour and solubility. Progressive delicate processing strategies can present an answer to this, providing an alternative choice to acid precipitation, which can be cheaper and simpler to make use of, however which will increase product loss and reduces performance.

What delicate strategies can be utilized? One vital improvement has been in using polymer or ceramic membranes to filter the fabric stream. It’s been confirmed within the dairy business, and is now transferring into plant protein extraction. Membrane filtration delivers greater yields and higher performance than acid precipitation, and is extra ecologically pleasant. By combining totally different membrane and processing situations at totally different levels, you may extract totally different proteins with totally different functionalities.

Are there hurdles to utilizing membranes?

Plant proteins can result in elevated fouling of membranes, as a result of a wide range of mechanisms: the excessive viscosity already talked about, for instance. Strategies comparable to ultrasound or nano bubbles, or adapting the pretreatment, might be able to remedy this problem. Moreover, there’s a number of analysis and improvement going down on the membranes themselves, for instance adapting the polarity, which can cut back the flexibility of polyphenolics to connect and block the membrane pores. We’d like one of these innovation to optimise the potential of the plant proteins.

How can producers ship that innovation?

Fortunately, we don’t have to begin fully ‘from scratch’: each producers and meals analysis firms like NIZO have collected a number of knowledge that may be useful. At NIZO, for instance, we have now a really broad vary of information that can be utilized to assist choose the perfect start line, or the optimum subsequent step, together with exploring which plant proteins may be capable of ship the required performance.

Producers, however, have plenty of in-depth knowledge on their particular processes and merchandise. And with sensors now so available, they’ll accumulate much more, at each stage of processing. This knowledge might present perception into particular alternatives for optimisation. Strategies comparable to modelling and synthetic intelligence (AI) are key to exploiting such knowledge, to allow each a sooner design trajectory and a better success price for course of optimisations.

How can strategies comparable to modelling and AI give producers a ‘serving to hand’?

Modelling, for instance, might help ‘fill within the blanks’ of lacking knowledge: consider utilizing high-throughput screening to outline optimum hydrolysis situations. AI can then take a look at your complete knowledge panorama and discover patterns people won’t see. Nonetheless, AI outcomes are removed from good; you continue to want

educated people to sift via the outcomes, to filter out the unrealistic AI-generated solutions and outcomes.

With all of the challenges, is it value it for manufactures to look past the ‘low-hanging fruit’?

The business has solely touched the floor of what we are able to do with plant proteins. Can they be sustainable? Sure. However they’ll additionally make good enterprise and monetary sense for producers, particularly if you happen to can extract all of the potential worth. You want an understanding of each processing strategies and protein sources. And it is advisable take a holistic strategy, which seems to be on the course of from begin to end. It’s a serious problem for the business, and we’re simply firstly of the journey, however we imagine the payoff might be greater than well worth the effort and investments.

[ad_2]